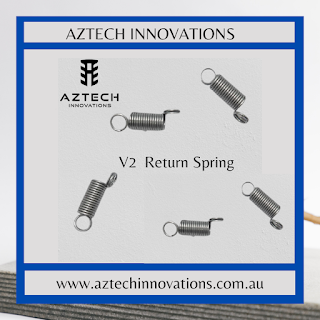

Before jumping onto the advantages brought about by the trigger and return spring, let us understand its mechanism and the benefits that it offers. The trigger and v2 tappet return springs are generally placed just behind the trigger of your firearm. As the trigger is pulled, it will return to its original position upon the release of the trigger.

|

| V2 Gearbox Trigger Spring |

There are

several kinds of trigger and return springs as there are various kinds of

triggers that are made available due to the designs of the firearm over the

years. A few of them might be torsion, compression as well as torsion springs.

You will surely come across a hammer that would be pushing up on the v2 gearbox trigger spring when there is a pullover of the

trigger, so once the trigger is off, the spring would push itself back on the

hammer causing this trigger to return back to its original place is what mainly

its mechanism lies.

So, let us dive into a few of the

benefits that are offered by this kind of spring!

Ease of mechanism

Each of the mechanisms of the

trigger arrives with its own benefits. The initial kind of trigger that was

used was the single-action trigger. It consisted of the slightest, shortest,

and the smoothest of pull along with its mechanism that is less complicated.

A constant pull

The mechanism of the v2 tappet return springs is also well-known for its constant ability from one shot to the rest so that there is no need for any kind of adaptation in the methods that are required for the exact precision here.

No additional effort

With the v2 gearbox trigger spring, users become capable of firing off the gum with the striker

still cocked or not. It is the characteristics that are pretty much helpful for

the military and self-defense firearms, making it the most convenient option.

Convenient

Comments

Post a Comment